The performance of 15-degree siding nails in terms of resistance to vibration or movement depends on various factors including the material composition, length, diameter, installation method, and specific application requirements.

Here’s how they typically perform:

- Material Composition: 15-degree siding nails are typically made from high-strength steel or corrosion-resistant materials such as stainless steel or aluminum. The choice of material affects the nail’s ability to withstand vibration or movement without bending, breaking, or loosening.

- Length and Diameter: Longer and thicker nails generally offer better resistance to vibration or movement due to their increased cross-sectional area and embedment depth. They provide greater structural support and anchorage, reducing the risk of nail displacement or failure under dynamic loading conditions.

- Installation Method: Proper installation techniques, such as driving the nails perpendicular to the siding and ensuring adequate penetration into the underlying substrate, are essential for maximizing resistance to vibration or movement. Nails that are driven at an angle or insufficiently embedded may be more susceptible to loosening or dislodgment over time.

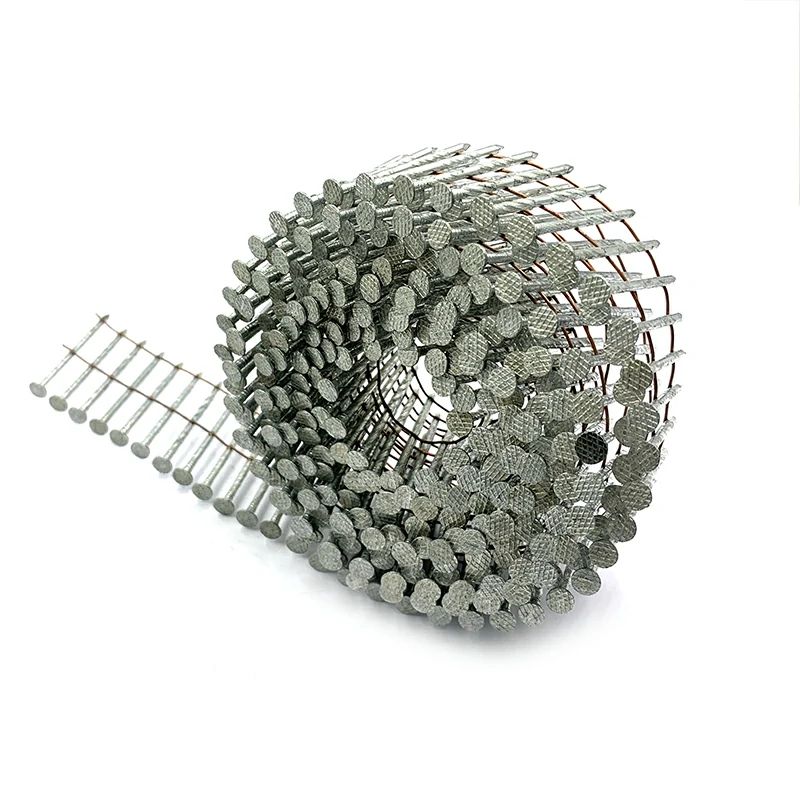

- Nail Head Design: The design of the nail head can also influence its resistance to vibration or movement. Siding nails typically feature a wide,15 degree siding nails flat head that distributes applied loads more evenly and provides better holding power against lateral forces, minimizing the risk of nail pull-out or shearing.

- Substrate Material: The type and condition of the substrate material can affect the performance of siding nails in resisting vibration or movement. Nails driven into solid wood substrates generally offer better resistance than those installed in softer or less stable materials such as vinyl or fiber cement siding.

- Environmental Factors: Environmental conditions, such as exposure to wind, temperature variations, and moisture, can affect the performance of siding nails in resisting vibration or movement. Corrosion-resistant coatings or materials can help mitigate the detrimental effects of environmental factors on nail performance and longevity.

Overall, 15-degree siding nails can provide effective resistance to vibration or movement when properly selected, installed, and maintained. However, it’s essential to consider factors such as material composition, length, diameter, installation method, substrate material, and environmental conditions to ensure optimal performance and durability over time. Regular inspection and maintenance can help identify any signs of loosening or displacement and address them promptly to maintain the integrity of the siding installation.

Leave a Reply